|

Vol 4 Issue 2 August 2010 |

|

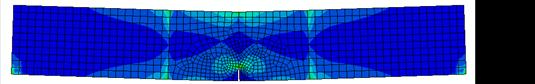

Above Image: ARC researchers add a notch to beams made using common BBR molds, eliminating the need for metal bars completely. |

|

What You Getwith 3D-Moveü SI /US units ü Static/dynamic analysis ü Uniform contact pressure distribution (circle, ellipse and rectangle) ü Non-uniform contact pressure distribution from database ü Non-highway vehicle (end-dump truck, forklift) loading ü Braking/non-braking condition (interface shear stresses) ü Dynamic variation of tire load (dynamic loading coefficient) ü Dynamic modulus, |E*|, from lab data or using the Witczak model for asphalt materials ü Response computations at an array of points ü Output of results in text, tabular, or graphical mode and as Microsoft Excel files ü Help and examples

|

|

Download 3D-Move Now!

UNR Releases 3D-Move Analysis

This powerful new modeling software lets you analyze pavement response under a variety of vehicle loading conditions

3-D Move, the versatile, free program from the University of Nevada Reno, uses a continuum-based finite-layer approach to account for pavement response factors such as moving loads, three-dimensional contact stress distributions (normal and shear) of any shape, and viscoelastic material characterization for the pavement layers.

The finite-layer approach adopted in 3D-Move treats each pavement layer as a continuum and uses the Fourier transform technique to handle complex surface loadings such as multiple loads and non-uniform tire pavement contact stress distribution.

This approach accounts for tire imprints of any shape, including those generated by wide-base tires.

3D-Move is computationally more efficient than moving load models based on the finite element method.

Because 3D-Move accommodates viscoelastic material properties, it is ideal for modeling asphalt concrete (AC) layers and studying pavement response as a function of vehicle speed. The adoption of frequency-domain solutions in 3D-Move means that frequency sweep test data of AC mixtures can be used directly in the analysis.

Join the 3D-Move Discussion Group at http://3d-move.finddiscussion.com to give feedback or post questions.

Click HERE to read the entire article, including the six types of loading computed in 3D-Move Analysis.

|

|

Please visit the ARC website to find references and links to publications, conference proceedings, presentations, posters and other useful information. |

|

3D-Move determines the contact pressure distribution (uniform or non-uniform) of an 18-wheel tractor-semitrailer by computing the load distribution on the tires during normal highway travel and on the axles during braking. |

|

Asphalt Lubricity Test The success of warm mix asphalt (WMA) field trials has prompted the development of mix design procedures and specifications to allow state agencies to take advantage of these technologies. The lack of procedures to evaluate the impacts of WMA technologies on asphalt binder and mixture workability has been a major impediment to the implementation of WMA (until now). Click HERE for more. Bitumen Bond Strength (BBS) Test Quantifying adhesion between bitumen binders and aggregates demands simple, inexpensive test methods as the road building industry moves toward performance-based specifications. The Pneumatic Adhesion Tensile Testing Instrument, commonly known as PATTI and originally developed for use in the painting industry, is identified as an appropriate test device for the newly proposed Bitumen Bond Strength (BBS) test. Click HERE for more.

Thermal Cracking Characterization Using the Single-Edge Notched Bending Test Current test methods to address low-temperature cracking, such as the Bending Beam Rheometer (BBR), characterize the material in the linear viscoelastic domain at small strain levels and therefore do not provide the whole picture for thermal cracking characterization. A more appropriate approach is to use the principles of fracture mechanics to minimize low-temperature cracking. Click HERE for more.

|

|

Three New Tests from UW-Madison Quantify Critical Properties of Engineered Paving Materials

Research at UW-Madison is generating innovative procedures for selecting modifiers, additives, and aggregate–binder combinations to enhance the internal bond of asphalt mixes, the workability of warm mixes and the low-temperature performance of roads.

|

|

Finite element modeling simulations indicate the advantages of using BBR geometry with a notch. No stress discontinuities are observed in the proposed geometry. The adhesion problem between binder and metal bars is avoided. |

|

“Viscosity reduction is not the only mechanism by which warm mix additives allow for compaction at reduced temperatures. Internal coefficient of friction is a key mechanism that contributes to the effects of WMA additives on mixture workability.” Andrew Hanz Task Leader for Warm Mix Work Element E1c-1 |

|

To remove your name from our mailing list, please click here. Questions or comments? E-mail us at psebaaly@unr.edu or call 775-784-6565. |