|

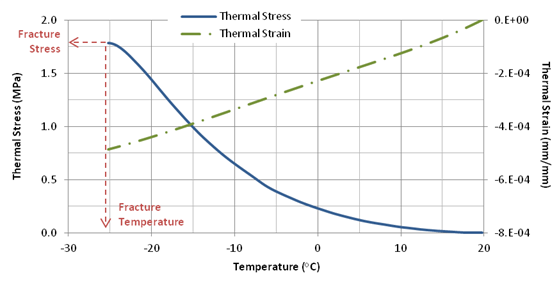

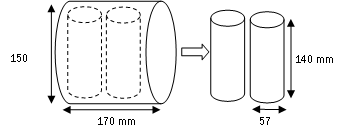

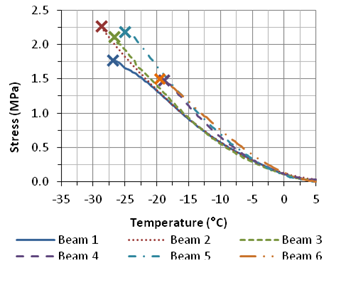

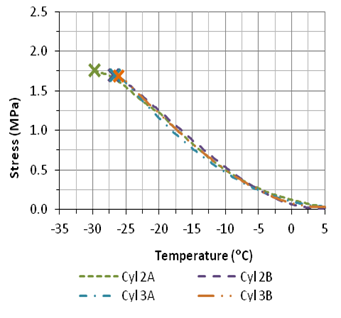

UNR Updates the Thermal Stress Restrained Specimen Test Characterization of Low-Temperature Properties of Asphalt Mixtures is Expanded The Thermal Stress Restrained Specimen Test (TSRST) developed as part of the Strategic Highway Research Program (SHRP) has been used to evaluate the failure properties of asphalt mixtures at low temperatures. The TSRST has been used under varying conditions, and TSRST results have been correlated with field performance of asphalt pavements. Fracture temperatures have been generally consistent; however, the stress buildup curve and fracture stress have been variable, and this has limited the use of the test. Now the research team at the University of Nevada, Reno has improved the procedure so additional low-temperature properties of asphalt mixtures can be characterized. Improvements in sample preparation, setup, testing conditions, and data analysis pave the way for new uses of the test beyond its original fracture temperature and stress functions, allowing greater understanding of the low-temperature thermal properties of asphalt mixtures and increased use of the test by industry. Updated Sample Preparation Traditionally, a beam specimen has been subjected to a cooling rate of 10° C per hour from an initial temperature of 5°C, while a constant specimen height is maintained. The ARC research team at the University of Nevada–Reno has replaced the traditional beam specimen with a cylindrical specimen cored from the side of a Superpave gyratory compacted (SGC) specimen (Figure 1). This sample preparation procedure offers several advantages. · Improved repeatability of the stress build-up curve and fracture stress (Figure 2). · Improved repeatability of density and overall volumetric control through the use of the Superpave gyratory compactor for specimen fabrication. · Better replication of field thermal loading conditions through the testing of specimens along the axis perpendicular to the direction of compaction. · Cylindrical specimens from field cores (with asphalt lift thickness ≥ 65 mm). |

|

Figure 1. Side core TSRST cylinders from a Superpave gyratory compacted specimen |

|

|

|

Figure 2. Thermal build-up stress for (a) beam and (b) side core cylindrical specimens

(a) |

|

(b) |

|

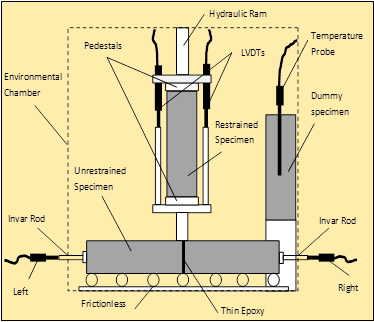

Enhanced Setup Improvements in the TSRST setup include modifications to the end platens and gluing apparatus and adhesive, as well as the addition of a modular feature for measuring the thermal strain of an unrestrained specimen concurrently with the thermal stress of the restrained specimen (Figure 3).

Figure 3. Details of the enhanced TSRST setup |

|

Test Conditions Revisited UNR researchers are assessing the influence of TSRST cooling rate, initial start temperature, and thermal cycling on the low-temperature properties of asphalt mixtures. Performing the test at a fast cooling rate may result in a large temperature lag between the chamber, the surface of the specimen, and the core of the specimen. Performing the test at a cooling rate representative of field conditions, such as 2.5°C per hour, significantly increases the time required to complete the test. |

|

What’s more, physical hardening effects may be introduced to the mixture when the specimen is conditioned to a cooler initial start temperature, such as the standard 5°C. Such effects may be reduced by selecting a warmer initial start temperature. Further, the thermal hysteresis as a result of thermal cycling in the TSRST has been observed through changes in the low-temperature properties of asphalt mixtures. The quantification of this effect will lead to better prediction of the low-temperature behavior of asphalt pavements.

Data Analysis Techniques Expanded The synchronized recording of both thermal stress (restrained specimen) and thermal strain (unrestrained specimen) values during testing allows for the determination of the thermal relaxation modulus (EThR) of the asphalt mixture using the linear viscoelastic Boltzmann constitutive equation where σ(t) is the thermal stress and ε(t) is the thermal strain.

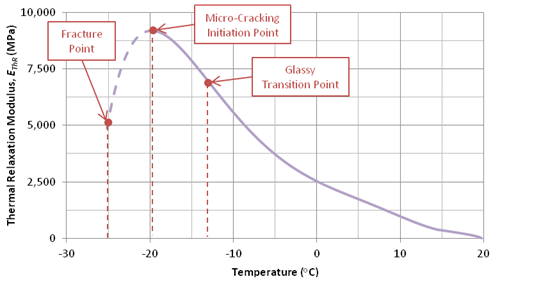

For example, Figure 4 shows the TSRST results as well as the computed thermal relaxation modulus for a PG64-22 dense-graded hot mix asphalt. The interpretation of the results allows for the determination of the following thermal properties of the mixture: Glassy Transition Temperature = -12.9 °C Glassy Transition Thermal Modulus = 6,900 MPa Micro-Cracking Initiation Temperature = -19.9 °C Micro-Cracking Initiation Stress = 1.4 MPa Thermal Modulus at Micro-Cracking Initiation = 9,190 MPa Fracture Temperature = -25.3 °C Fracture Stress = 1.8 MPa

(a)

(b) Figure 4. (a) Thermal stress and strain build-up and (b) thermal relaxation modulus

|

|

These enhancements in sample preparation, setup, testing conditions, and data analysis of the Thermal Stress Restrained Specimen Test by ARC researchers are aimed at providing industry with greater capacity to characterize low-temperature thermal properties of asphalt mixtures and ultimately to contribute to the construction of roads that are more cold resistant and longer lasting.

References Monismith, C. L., Secor, G. A. and Secor, K. E. (1965). “Temperature Induced Stresses and Deformations in Asphalt Concrete,” Journal of the Association of Asphalt Pavement Technologists, Vol. 34, pp. 245-285. Jung, D. H., Vinson, T. S. (1994). “SHRP-A-400: Low-Temperature Cracking: Test Selection,” Strategic Highway Research Program, National Research Council. Washington D.C. Velasquez, R., Gibson, N., Clyne, T., Turos, M., Marasteanu, M. (2008). “Investigation of Low-Temperature Cracking in Asphalt Mixtures using TSRST,” Proceedings, 6th RILEM International Conference on Cracking in Pavements, RILEM, Chicago, pp. 405-414. Fortier, R., Vinson, T. S. (1998). “Low-temperature cracking and aging performance of modified asphalt concrete specimens,” Transportation Research Record No. 1630, Transportation Research Board of the National Academies, Washington, D.C. Pucci, T., Dumont, A. G., Di Benedetto, H. (2004). “Thermomechanical and Mechanical Behavior of Asphalt Mixtures at Cold Temperature: Road and Laboratory Investigations,” Road materials and pavement design, vol. 5, no. 1: 45-72. Marasteanu, M., Zofka, A., Turos, M., Li, X., Velasquez, R., Buttler, W., Paulino, G., Braham, A., Dave, E., Ojo, J., Bahia, H., Williams, C., Bausano, J., Gallistel, A., McGraw, J. (2007). “Investigation of Low Temperature Cracking in Asphalt: Pavements National Pooled Fund Study 776,” Minnesota Department of Transportation, MN/RC 2007-43. Ksnerva, H. K., Vinson, T.S., and Zeng, H. (1994). “SHRP-A-401: Low-Temperature Cracking: Field Validation of the Thermal Stress Restrained Specimen Test,” Strategic Highway Research Program, National Research Council, Washington D.C. Zubeck, H. K., Vinson, T. S. (1996). “Prediction of Low-Temperature Cracking of Asphalt Concrete Mixtures with Thermal Stress Restrained Specimen Test Results,” Transportation Research Record No. 1545, Transportation Research Boards of the National Academics, Washington.

|