|

ARC Members Advance Mixture Testing for Rutting Resistance and Low-Temperature Properties

Test: Flow Number (FN) Testing Purpose: To measure the rutting resistance of asphalt Developed by: Various Used since: In 2004, the National Cooperative Highway Research Program (NCHRP) 9-19 panel recommended flow number testing as a complement to the dynamic modulus test (the recommended primary simple performance test for rutting) Current update: To evaluate five flow number approaches with the aim of establishing FN standards Updates by: The Mixture and Construction Expert Task Group, with participation by ARC members Advanced Asphalt Technologies LLC, the University of Nevada–Reno, the National Center for Asphalt Technology, and others

As the Asphalt Mixture Performance Tester (AMPT) has become more widely accepted for measuring the dynamic modulus and rutting resistance of asphalt concrete mixtures, one shortcoming has become increasingly apparent. Not fully addressed during the AMPT’s development was standardized flow number (FN) testing and analysis to determine an asphalt mixture’s rutting resistance. The FHWA Mixture and Construction Expert Task Group (ETG) has determined that the need for flow number standards is critical, especially as they relate to performance testing in asphalt mixture design and acceptance. Click HERE for more. |

|

Asphalt Research Correspondent |

|

An FHWA Research Program Comprising Western Research Institute, Texas A&M University, University of Wisconsin-Madison, University of Nevada-Reno, Advanced Asphalt Technologies and the National Center for Asphalt Technology. |

|

Vol 6 Issue 1 August 2012 |

|

Test: Thermal Stress Restrained Specimen Test Purpose: To evaluate the failure properties of asphalt mixtures at low temperatures Developed: As part of the Strategic Highway Research Program Used since: 1994 Current Updates: Improvements to allow more low-temp properties of asphalt mixtures to be characterized Updates by: University of Nevada–Reno |

|

To remove your name from our mailing list, please click here. Questions or comments? E-mail us at psebaaly@unr.edu or call 775-784-6565.

Please Visit the ARC website to find references and links to publications, presentations and other useful information. |

|

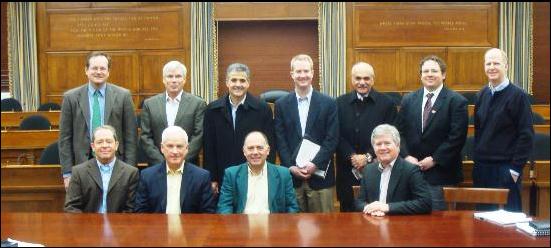

In January, ARC members met with Jamie Brown, staff member of the House of Representatives Committee on Science, Space and Technology Subcommittee on Technology and Innovation, to discuss how asphalt research is improving the durability of roads and making federal dollars go further. Shown left to right are (first row) Michael Harnsberger, WRI; Dallas Little, Texas A&M University; Jean-Pascal Planche and Donald Collins, WRI; (second row) Ramon Bonaquist, Advanced Asphalt Technologies; Fred Turner, WRI; Peter Sebaaly, University of Nevada, Reno; Jamie Brown; Hussain Bahia and Andrew Hanz, University of Wisconsin-Madison, and David French, ENS Resources. |

|

The Thermal Stress Restrained Specimen Test (TSRST) has been used under varying conditions, and TSRST results have been correlated with field performance of asphalt pavements. Low-temperature fracture temperatures have been generally consistent; however, the stress buildup curve and fracture stress have been variable, and this has limited the use of the test. Now the research team at the University of Nevada, Reno has improved sample preparation, setup, testing conditions, and data analysis to pave the way for new uses of the TSRST beyond its original fracture temperature and stress functions, allowing greater understanding of the low-temperature thermal properties of asphalt mixtures and increased use of the test by industry. Click HERE for more. |