|

Asphalt Research Correspondent |

|

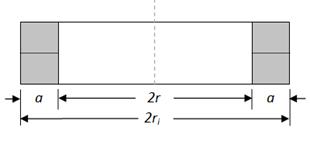

University of Wisconsin Madison leads testing of the Linear Amplitude Sweep (LAS) procedure to specify fatigue resistance Recent research has demonstrated that fracture is the fatigue damage mechanism in asphalt binders under Time Sweep testing in the dynamic shear rheometer (DSR). The Time Sweep (TS) was developed during NCHRP Project 9-10 to improve the current Performance Grade (PG) specification to evaluate asphalt fatigue resistance. TS is based on the definition of fatigue damage as the degradation of material integrity under repeated loading. Pavement structure and traffic loading are accounted for by the selection of load amplitude. The Time Sweep test, however, is not practical for specifying asphalt binder fatigue resistance because of the uncertainty in testing times. Fracture manifests as a circumferential crack which initiates at the periphery of the asphalt sample and propagates inward as number of loading cycles increases, effectively reducing the sample radius. This fracture leads to apparent modulus reduction. It has been demonstrated that reductions in loading resistance are directly related to crack growth, and hence under constant deflection angle amplitude time sweep testing, changes in torque can be used to predict crack length. These findings have led to re-examination of the LAS test, in which failure is assumed to occur by a similar damage mechanism. To evaluate if the LAS test induces fatigue damage, ARC researchers at the University of Wisconsin Madison compared trends in crack growth rates in the TS and LAS tests. Figure 1 depicts a fracture during DSR testing. Crack growth effectively reduces the sample radius, hence, crack length is taken to be the difference between the initial and intact radius. A photograph of a binder sample after LAS testing (Figure 2) shows a fractured outer edge, characterized by fine radial line, and an intact sample center. The fracture morphology of the asphalt binders following the LAS test is consistent with asphalt binders under time sweep loading and with other materials under similar loading conditions. Crack length has been shown to be directly related to loading resistance, which allows for estimation of crack length using DSR measurements.

Figure 1. DSR fracture depiction.

Figure 2. Binder specimen after LAS testing.

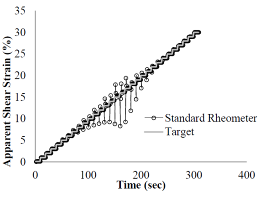

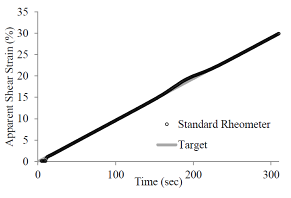

Modification of LAS Standard Procedure While the current LAS testing procedure and corresponding analysis framework as described as part of AASHTO TP101-12 are better than the previous specification for fatigue characterization of asphalt binders, it was found that further improvements relating to the observed crack growth during loading could be made using a fracture mechanics framework. Furthermore, a number of standard grade rheometers have not been sufficiently accurate when applying the step-wise amplitude sweep procedure used in the current LAS standard. In response to these observations and a recent study explaining the damage mechanism under LAS testing (Hintz, 2012), ARC researchers at the University of Wisconsin Madison proposed a modified testing procedure consisting of a continuous oscillatory amplitude sweep rather than a step-wise amplitude sweep (Figure 3). The continuous oscillatory amplitude sweep has been shown to yield results equivalent to those of the step-wise amplitude sweep (Figure 4), while being simpler to perform using standard rheometers. The procedure consists of the same range of loading amplitudes (i.e., 0.1% to 30% shear strain) and the same total testing time (310 seconds) as the current testing procedure.

Figure 3. Comparison of the ability of standard rheometers to perform step-wise strain amplitude sweep (a) and the continuous strain sweep (b).

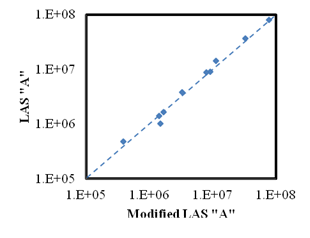

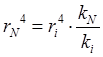

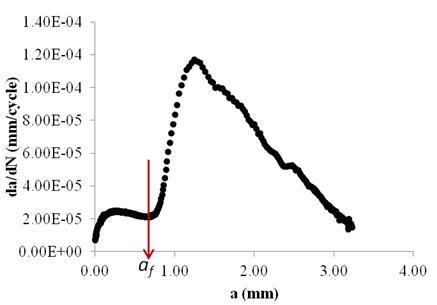

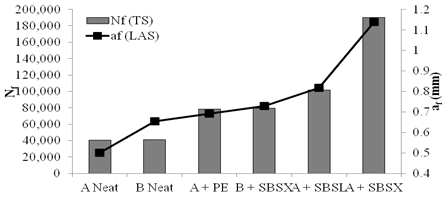

Figure 4. Comparison of fatigue law parameter “A” determined from modified LAS test and the current LAS test (“A” is the intercept value of the fatigue power law Nf vs. strain curve at γ=1%). Furthermore, a fracture-based analysis framework was also proposed for the modified LAS test that allows for a quick ranking of the relative damage tolerance of binders without the need for rigorous VECD analyses. Crack lengths and corresponding crack growth rates can be calculated using Equation 1, where k = T/ϕ, (T = torque, ϕ = deflection angle), and ri and rN are the effective sample radius at the beginning of the test (e.g. 4 mm) and at the Nth cycle, respectively. The modified LAS test revealed two peaks in crack growth rate, a small local peak followed by a very rapid increase in crack growth rate to the absolute peak. The local minimum crack growth rate prior to the rapid increase (denoted as af in Figure 5) coincides with the point where loading resistance (torque) begins decreasing rapidly and thus is deemed a reasonable failure criterion. On the basis of this analysis, it was determined that one means to efficiently rank materials’ relative damage tolerance is to conduct the modified LAS test and calculate the crack length at failure, af, corresponding to the crack length at the local minimum in crack growth rate as depicted in Figure 5. A higher crack length at failure is desirable as it indicates the binder can withstand a greater crack length prior to the rapid crack propagation. The ranking of asphalt binders according to their crack length at failure using the modified LAS test was found to be similar to fatigue life measured in the TS test as shown in Figure 6. Note that time sweep fatigue failure is defined as the peak in crack growth rate, found to occur at a crack length of 0.3mm for all binders, given standard 8mm parallel plate geometry is used (4).

Figure 5. Crack growth rate as a function of crack length in modified LAS test.

Figure 6. Comparison of crack length at failure from the LAS test and number of cycles to failure determined from the TS test. The University of Wisconsin Madison research team incorporated changes and modifications to the practice and analysis in an updated draft AASHTO standard procedure presented to the Federal Highway Administration Binder Expert Task Group in Minneapolis in September 2012; and inner- and inter-laboratory ruggedness testing programs are underway to further evaluate the proposed modifications. The modified testing procedure and corresponding analysis are also included in a paper titled “Simplification of the Linear Amplitude Sweep (LAS) Test and Specification Parameter” (Hintz and Bahia, 2012), presented at the 2013 Annual Meeting of the Transportation Research Board. Contacts: Hussain U. Bahia, Ph.D., Professor, bahia@engr.wisc.edu Hassan A. Tabatabaee, Ph.D., Research Associate, tabatabaee@wisc.edu

References 1. Bahia, H. U., Hanson, D. I., Zeng, M., Zhai, H., Khatri, M. A., and R.M. Anderson. Characterization of Modified Asphalt Binders in Superpave Mix Design, NCHRP Report 459, National Academy Press, Washington, D.C., 2001. 2. Johnson, C.M. and H.U. Bahia. Evaluation of an Accelerated Procedure for Fatigue Characterization of Asphalt Binders. Submitted for publication in Road Materials and Pavement Design. 2010. 3. Hintz, C., Velasquez, R., and H. Bahia. Modification and Validation of the Linear Amplitude Sweep Test for Binder Fatigue Specification. Submitted for publication in Transportation Research Record, Journal of the Transportation Research Board, 2010. 4. Hintz, C. Understanding Mechanisms Leading to Asphalt Binder Fatigue, PhD Dissertation, University of Wisconsin-Madison, 2012.

|