|

|

|

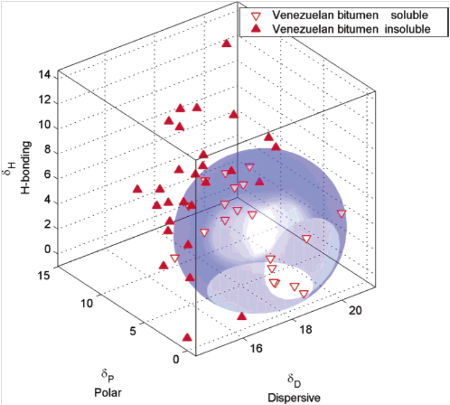

Compatibility of RAP and Virgin Binders The Bitumen Solubility Model provides an approach to determining a material’s internal stability When reclaimed asphalt pavement (RAP) is mixed with virgin asphalt and aggregate to build a new road, the virgin binder acts as a solvent of sorts that stimulates mixing with the RAP asphalt. The result is a new asphalt with unique properties. Determining how much the RAP and virgin asphalts blend in a RAP mix is a complex problem, with the degree of blending significantly affecting the asphalt properties of the RAP mix. Because of variables in binder compatibilities, particle sizes, mixing temperature, and time, complete blending of the RAP and virgin asphalts cannot be assumed. In the field, this incomplete mixing results in a mix that can be too stiff, too soft, or have other unpredicted properties. On the other hand, the degree of mixing, the fraction of RAP that is mobilized, and the compatibility of the recycled and virgin materials should be directly related. WRI has set out to determine the degree to which RAP and virgin binders blend and what effects the blending has on the resulting material properties. There is much to gain from determining some fundamental chemical properties of virgin, recycled, and blended materials. For instance, if only a fraction of the asphalt in the RAP actually blends with the virgin binder, what fraction is it? Is the blended fraction representative of the entire RAP binder or does it contain a disproportionate amount of asphaltene or maltene fractions? These questions are being answered using chromatographic separations and other analytical methods developed at WRI. The results are being used to determine the RAP-virgin asphalt blend compatibility for the composition of materials most likely to exist in the final pavement. By gaining a better understanding of the fundamental chemistry of mixing RAP and virgin asphalts, WRI is seeking to improve the analysis and prediction of blended asphalt properties. From that fundamental understanding, rapid test methods can be developed to characterize the properties of RAP and virgin asphalts to accurately predict the asphalt properties and performance of the resulting mix. RAP binders from four different sources were extracted and characterized. Two separate extractions were performed on each RAP source using two different solvent systems. One was a mixture of toluene and ethanol (85:15 by volume), which is used routinely to extract asphalt from aggregate completely. The other solvent system was cyclohexane, which has similar solubility parameters to asphalt and, as such, should provide an approximation of what fraction of RAP will likely blend with a virgin binder. In most cases, the cyclohexane extractions yielded slightly less asphalt from the RAP than the toluene and ethanol extractions. Physical testing of the extracted RAP binders using dynamic shear rheology (DSR) was performed to determine whether the binders were different both chemically and physically. In fact, the cyclohexane-extracted RAP binders were typically less stiff than the toluene:ethanol analogues. This is an indication that a fraction of the non-solvent phase of the RAP binder may be less likely to blend with the virgin asphalt. Though some modification to the cyclohexane extraction protocol might be needed to suit this purpose, it appears to provide an indication of the extent of RAP binder that is mixing when blended with virgin materials. Following RAP characterization, virgin binders were blended with the RAP binders at concentrations of 0, 15, and 40%. Two virgin binders, one with good compatibility and one with poor, were selected. Blended materials were characterized using Automated Flocculation Titrimetry (AFT), chromatography, and rheology. The Asphaltene Determinator (AD) was used to evaluate the chemical composition of the binders. The AD is a quick, automated method for separating binders into fractions based on solubility. In general, the AD results indicated that the cyclohexane extracted binders were lower in asphaltene content. The data support the hypothesis that binder mixing is not complete when RAP and virgin asphalts are blended. The lower asphaltene content indicates that some asphaltene materials are strongly adsorbed to the RAP aggregate and most likely do not blend. WRI also used AFT (ASTM D6703-01) on the extracted, virgin, and blended binders to determine the compatibility of each system. Results have been mixed. The extracted samples were blended at several concentrations with two RTFO-aged binders, BI-0001 and BI-0002. In most cases, results indicate an increase in asphaltene content, as expected, and an increase in the polarity for the asphalt blends. Initially it was believed that the increase in asphaltene content was accompanied by an improvement in the solvent power of the maltenes. The stiffening observed in the rheological data, however, indicates that the AFT parameters—usually attributed to the maltenes and whole asphalt—are a better indication of the total polarity of the system and not necessarily the compatibility of the blended binders. The data are mixed, but the sample set is not finished. Samples obtained from the NCHRP 9-12 project—in which extracted RAP binders actually softened the virgin binders—are being analyzed using one-dimensional AFT to determine compatibility and to see if compatibility issues might explain the results. Research at WRI suggests that a multi-dimensional compatibility test would be best for determining aged and virgin binder blend compatibility and predicting performance. One-Dimensional vs. Three-Dimensional Solubility Testing To develop a better understanding of the properties of RAP and virgin binder blends, more than the one-dimensional solubility determination provided by the AFT (ASTM D6703-01) is needed. The Bitumen Solubility Model, or BISOM test, developed at Nynas Bitumen is a modified approach to determining the internal stability, or compatibility, of a material (Redelius 2004; Hansen 2007). The BISOM method uses the AFT instrument to determine a multi-dimensional material compatibility. The BISOM test is a suite of Heithaus titrations of bitumen dissolved in toluene with different solvents of known Hansen solubility parameters. Each solvent is selected to determine particular chemical characteristics relating to the stability of the system, a measurement of polar, dispersive, and hydrogen-bonding characteristics. Three separate asphalt samples are dissolved in toluene and each is titrated in the AFT with a poor solvent that corresponds to internal chemical characteristics. For example, titration with iso-octane provides an indication of material polarity, while methyl-ethyl ketone gives an indication of the hydrogen bonding nature, and 2-ethyl-1-hexanol the dispersive characteristics. The results of the titrations can then be plotted using a program called HSP3D, developed at WRI in conjunction with Nynas, to present a 3-dimensional profile of a binder system (figure 1). In the WRI study, AFT was used for a one-dimensional compatibility measurement focused primarily on the precipitation of asphaltenes using iso-octane. It provided an indication of the polar character of the blended binders only. While this works well for unmodified, virgin binders, it has shown to be deficient for determining the compatibility of the blended aged and virgin binders because the highly polar nature of aged binders overwhelms the determination of the character of the solvent fraction. Next, WRI will test the same materials and blends using the BISOM method. Three-dimensional analysis of their compatibility profiles will be used to help demonstrate the effects of blending aged and virgin binders and to relate those properties to the physical properties of the materials. The results are expected to help in the prediction of which aged and virgin binders are most likely to perform well when blended—and thus perform well as RAP pavements. |

|

Initially it was believed that the increase in asphaltene content was accompanied by an improvement in the solvent power of the maltenes. The stiffening observed in the rheological data, however, indicates that the AFT parameters—usually attributed to the maltenes and whole asphalt—are a better indication of the total polarity of the system and not necessarily the compatibility of the blended binders. The data are mixed, but the sample set is not finished. Samples obtained from the NCHRP 9-12 project—in which extracted RAP binders actually softened the virgin binders—are being analyzed using one-dimensional AFT to determine compatibility and to see if compatibility issues might explain the results. Research at WRI suggests that a multi-dimensional compatibility test would be best for determining aged and virgin binder blend compatibility and predicting performance. One-Dimensional vs. Three-Dimensional Solubility Testing To develop a better understanding of the properties of RAP and virgin binder blends, more than the one-dimensional solubility determination provided by the AFT (ASTM D6703-01) is needed. The Bitumen Solubility Model, or BISOM test, developed at Nynas Bitumen is a modified approach to determining the internal stability, or compatibility, of a material (Redelius 2004; Hansen 2007). The BISOM method uses the AFT instrument to determine a multi-dimensional material compatibility. The BISOM test is a suite of Heithaus titrations of bitumen dissolved in toluene with different solvents of known Hansen solubility parameters. Each solvent is selected to determine particular chemical characteristics relating to the stability of the system, a measurement of polar, dispersive, and hydrogen-bonding characteristics. Three separate asphalt samples are dissolved in toluene and each is titrated in the AFT with a poor solvent that corresponds to internal chemical characteristics. For example, titration with iso-octane provides an indication of material polarity, while methyl-ethyl ketone gives an indication of the hydrogen bonding nature, and 2-ethyl-1-hexanol the dispersive characteristics. The results of the titrations can then be plotted using a program called HSP3D, developed at WRI in conjunction with Nynas, to present a 3-dimensional profile of a binder system. In the WRI study, AFT was used for a one-dimensional compatibility measurement focused primarily on the precipitation of asphaltenes using iso-octane. It provided an indication of the polar character of the blended binders only. While this works well for unmodified, virgin binders, it has shown to be deficient for determining the compatibility of the blended aged and virgin binders because the highly polar nature of aged binders overwhelms the determination of the character of the solvent fraction. Next, WRI will test the same materials and blends using the BISOM method. Three-dimensional analysis of their compatibility profiles will be used to help demonstrate the effects of blending aged and virgin binders and to relate those properties to the physical properties of the materials. The results are expected to help in the prediction of which aged and virgin binders are most likely to perform well when blended—and thus perform well as RAP pavements. ARC |

|

Figure 1. Example of a 3-Dimensional solubility profile of a Venezuelan bitumen (Redelius 2004). |

|

Cited References Hansen, Charles M., 2007, Hansen Solubility Parameters of Asphalt, Bitumen, and Crude Oils, Hansen Solubility Parameters – A Users Handbook, CRC Press, 151-175. Redelius, P., 2004, Bitumen Solubility Model Using Hansen Solubility Parameters. Energy and Fuels, 18(4), 1087-1092. |