|

Asphalt Research Correspondent |

|

University of Nevada-Reno and University of Wisconsin-Madison Design System for High-Percentage RAP in Hot Mix Asphalt |

|

In the United States (U.S.) alone, demand for asphalt products is expected to increase 1.2% annually to nearly 40 million tons, or 211 million barrels, in 2011. About 85% of the total asphalt demand will go to asphalt paving applications (Roads and Bridges, 2007). Alongside demand, consistently rising construction, shipping, and manufacturing costs have generated a need for serious conservation movements within the asphalt industry. Beginning in the mid 1970s, recycling asphalt became a widely accepted practice, with more than 40 states practicing some form of pavement recycling between 1976 and 1982. Today, all 50 states accept the use of recycled pavements in some form, as either aggregate material or as binder replacement (Federal Highway Administration, 2010). At low recycled asphalt pavement (RAP) contents, there may not be enough old asphalt to significantly affect the properties of the virgin asphalt binder. At high percentages (i.e. more than 25% RAP), the hardened RAP binder may stiffen the mix and alter the mechanical properties of the mix. Consequently, well-developed design methods and analysis of the material properties for asphalt mixtures with high RAP contents are advisable. Evaluating the RAP materials consists of measuring the properties of the binder and aggregates of the reclaimed mix. Several research studies have been conducted to identify the best methods for separating and testing the binder and aggregates of the RAP materials but there have not been any standard procedures that agencies can use on a routine basis. In the case of the binder in the RAP, the two critical properties are: binder content and binder properties. The binder content of the RAP can be easily identified through the extraction process. However, measuring the properties of the binder is still a challenging process. Extracting and recovering the asphalt binder from the RAP materials faces the fundamental issues of the impact of the extraction/recovery process on the properties of the recovered binder and the health/environmental impact of the chemicals used in the process. These issues become very difficult to resolve when polymer-modified or crumb rubber modified binders are present in the RAP materials. In the case of the aggregates in the RAP, the two critical properties are: gradation and specific gravity. The gradation of the aggregates in the RAP materials can be easily evaluated through the extraction process. Determining the specific gravity of the RAP aggregates represents a challenge. Several techniques have been used in the past but there is not an accepted standard procedure. Binder Content and Aggregate Properties of RAP Materials The University of Nevada-Reno, in collaboration with the National Center for Asphalt Technology (NCAT), conducted a research study to investigate the influence of centrifuge, reflux and ignition oven extraction methods on extracted aggregate properties. The properties of the virgin aggregates (i.e. gradation and specific gravities) were compared to those of aggregates extracted from laboratory-produced (simulated) RAP from four different aggregate sources (two from the Eastern and two from the Western U.S.). Additionally, the extracted asphalt binder contents were compared to their corresponding true binder contents. The test results were further examined to determine the impact of the RAP aggregate properties on the voids in mineral aggregate (VMA) for mixtures incorporating different percentages of RAP. As a result of testing with the four aggregate sources, recommendations were made for the most appropriate method for estimating the RAP aggregate specific gravity based on an acceptable level of error in the VMA calculation of mixtures containing varying levels of RAP: The ignition/oven method gives the most accurate results for asphalt content of RAP. The solvent extraction methods do not appear to remove all of the aged binder from RAP, and consequently, RAP asphalt contents using these methods tend to be lower than they actually are. The RAP aggregate specific gravity (Gsb) is critical to an accurate determination of VMA. For high RAP content mix designs, the best method for determining the RAP aggregate specific gravity is to use a solvent extraction method (centrifuge or reflux) to recover the aggregate and then test the coarse and fine parts of the recovered aggregate using AASHTO T85 and T84, respectively. For RAP contents less than 25%, the net effect may be an error in the VMA determination of +/- 0.2%. As RAP contents approach 50%, the net effect may be an error in the VMA determination of +/- 0.4%. Another method for estimating the RAP aggregate Gsb is the approach of determining the maximum theoretical specific gravity (Gmm) of the RAP material using AASHTO T209. From the Gmm and the asphalt content of the RAP, the effective specific gravity (Gse) of the RAP aggregate can be determined. Although some agencies use the Gse for the RAP aggregate in the calculation of VMA, recent research findings strongly advise against this practice. Other agencies try to correct the Gse to an estimated Gsb using an assumed value for asphalt absorption. This correction is only reliable when the asphalt absorption can be assumed with confidence. The correction is very sensitive to the assumed asphalt absorption value and can lead to errors in VMA that are +/-0.5% or more. |

|

Figure 1: RAP binder contents (whiskers represent 95% confidence interval)

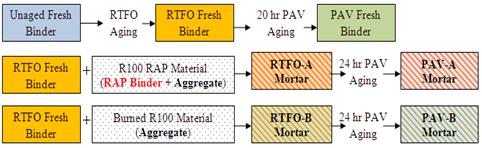

Characteristics of RAP Binder Methods currently available for quantifying the effect of the reclaimed binder on the mixture binder properties include chemical extraction and recovery of the reclaimed binder, back calculation from testing gyratory mixture samples, and testing samples cut from gyratory compacted samples in the Bending Beam Rheometer (BBR). However, chemical extraction and recovery is time consuming and the effects of the chemical solvents on the reclaimed binder are not well known. Similarly, the latter two methods are labor intensive and resource dependent. Moreover, the current methods do not take into account intermediate and high temperature pavement service conditions. Accordingly, there exists a need for a testing procedure that quantifies the effect of RAP and recycled asphalt shingles (RAS) on the fresh binder properties at all critical pavement temperatures. The approach should minimize labor and eliminate the need for binder extraction. Research conducted by the University of Wisconsin-Madison and University of Nevada-Reno within the Asphalt Research Consortium (ARC) has resulted in a testing procedure in which mortar and binder samples are tested in the BBR and Dynamic Shear Rheometer (DSR) to quantify the effect of RAP and RAS binder on the fresh binder continuous grade profile, allowing for an estimation of mixture binder properties at critical pavement temperatures. The testing procedure produces a RAP/RAS binder−fresh binder continuous grade improvement rate that is the rate of change of the fresh binder continuous grade per percentage fresh binder replaced by RAP/RAS binder. This allows users to estimate the performance grade of the mixture binder given any amount of RAP and RAS binder replacement within the mixture. Methodology In the proposed analysis procedure, three samples are tested at low, intermediate and high critical temperatures. These samples include one fresh binder and two mortar samples; the mortars are comprised of the same fresh binder and a single gradation aggregate source. The procedure is founded on the idea that if the two mortar samples are prepared with identical gradation and identical total asphalt content, using the same constituents, but one mortar sample contains a percentage of reclaimed binder (replacing an identical percentage of fresh binder), then any difference in properties between the mortar samples can be directly attributed to the percentage of reclaimed binder. If the properties of the fresh binder (also used for making the mortar samples) are also known, then the change in properties of the fresh binder due to blending with the reclaimed binder can be isolated. That is, if the continuous grade of the fresh binder is known, the mortar testing will allow for the estimation of the resulting continuous grade of the fresh binder-reclaimed binder blend. The following graphic illustrates the mortar preparation process and the distinction between the above-mentioned mortars for low temperature characterization.

Figure 2: Sample preparation procedure for RAP binder characterization

The advantages of this method are readily noted. The procedure eliminates the need, and variability associated with, chemical extraction and recovery; the reclaimed binder is directly characterized, without modification. In the analysis, there is no back calculation from mortar to binder; all calculations are in terms of binder, or blended binder, only. This not only reduces confusion in the calculations but will also reduce the procedural error and variability to testing error and variability only. Next, this method uses standard methods of binder specification at low, intermediate, and high temperatures, so the results are readily accessible to the user. Since testing is done at all critical temperature ranges in the pavement, this method allows for a full characterization profile of the reclaimed – fresh binder properties. Significant Findings The analytical procedure output as discussed is applicable only to the specific RAP and fresh binder source combination tested; it is expected that each RAP source will blend differently with each fresh binder source. To demonstrate the sensitivity of the proposed procedure to both RAP and fresh binder source, 10 RAP sources were blended with different fresh binder sources in 18 unique combinations and the blended binder ‘rate of improvement’ (Eq. 1) was calculated for each case. The rate of improvement was calculated by dividing the change in the fresh binder continuous grade by the percent of RAP used. The results of the analysis are presented in Table 1.

Table 1: Procedure Sensitivity to RAP Source and Virgin Binder PG

Highlighted in the table are the extreme values for the improvement rates; suggesting that treating all RAP and fresh binder sources as singular (the current methodology for RAP design) may be misleading. For example if we were to use 20% binder replacement, our virgin binder PG may be changed by as little as 1°C or as much as 11°C, a change of nearly two full performance grades at low temperature. The tiered approach to high percentage RAP design used currently in the AASHTO standards may be misleading. RAP sources may differ in total aging and composition, both of which may affect low temperature properties of asphalt pavement differently. Assuming similar effects without measuring them could lead to premature failures. Although not discussed here, similar findings at intermediate and high temperature ranges using the DSR also pointed to a need for more refined RAP characterization methods. Implications and Future Work The research hypothesis of the ARC team is that the effect of RAP on blended binder properties can be quantified using a continuous grade mortar testing approach using current Superpave binder testing equipment. Following the testing and analyses, some of which is presented herein, this hypothesis could be justified. Results revealed that the final blended binder grade is dependent on both the RAP source and the starting fresh binder grade. Likewise, chemical modification of the fresh binder influences the final blended binder grade. The binder analysis procedure appears suitable for use in capturing the blended binder properties at low, intermediate and high temperatures, and shows promise in replacing chemical extraction and recovery. Perhaps most importantly, the procedure is less material dependent when compared to asphalt-aggregate mixture testing and the cost of chemical extraction and recovery equipment. Any laboratory equipped to perform standard Superpave testing can handle the proposed procedure with no new equipment. The ARC continues to work on the proposed analysis procedure, specifically on the characterization of workability properties associated with high percentage RAP usage. DSR testing to isolate binder viscosity properties is currently underway. Alongside the workability testing, fracture characteristics of RAP mixtures are also being explored using the SENB device. Preliminary results have demonstrated that RAP has a significant and measurable effect on the fracture properties of virgin binder. References Pavement Recycling. (2010). Retrieved September 2010, from U.S. Department of Transportation, FHWA: http://www.fhwa.dot.gov/pavement/recycling/index.cfm U.S. asphalt demand to exceed 38 million tons in 2011. (2007). Retrieved September 2010, from Roads and Bridges: http://www.roadsbridges.com/U-S-asphalt-demand-to-exceed-38-million-tons-in-2011-newsPiece14912

|